Düsseldorf, June 10, 2025- Epson, a leading provider of robot and automation technology, presents its first collaborative industrial robot solution at the Automatica 2025. This enables an effective interaction between humans and the machine in industries such as production, logistics and the rapidly developing life science sector and thus increases efficiency and productivity. From autumn 2025, the solution will be offered as the first Collaborative Completion of Epson, which includes the new 6-axis robot AX6-A901S consisting of carbon lightweight construction and the compact EPSON RC-A101 control including the AX portal programming system.

“In the rapidly growing areas of biosciences and pharmaceutical industry, precise work processes and strict hygiene management are of great importance,” explains Volker Spanier, Head of Manufacturing Solutions from Epson. “In order to meet these requirements, the new collaborative robot of Epson is suitable for clean room. Thanks to its precise movements, the machine therefore also allows the activity itself in laboratories and pharmaceutical facilities.”

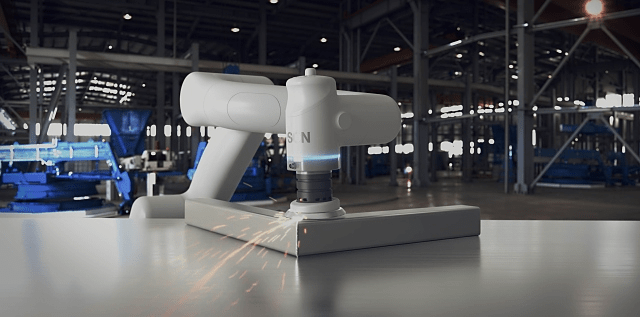

Important product features of the collaborative robot AX6-A901S by Epson:

Balanced design: The AX6-A901S moves a payload of up to 6 kg with an arm length of 900 mm. It has a particularly light and compact design, so that both its transport and its integration into existing production lines are very simple. Thanks to the compact dimensions, it can also be used in cramped environments. Compact and light controller: The Epson RC-A101 controller is suitable for installation on driverless transport vehicles (AGVS) and autonomous, mobile robots (AMRS). It has the dimensions B 440 x D 205 x H 135 mm and weighs less than 6 kg. This compact design also enables a very space -saving installation. Compatible with different power sources: The collaborative robot is compatible with power sources of 100 to 230 VAC or 48 VDC, so that it can be installed in environments with different power sources. Pure space compatibility: The AX6-A901S has clean room class 5 according to ISO 14644-1 and the protection class IP54. The smooth housing design without screw holes and sharp edges minimizes the collection of dust and thus the risk of contamination in clean room environments. Python programming: The programming environment supports the widespread programming language Python. This compatibility simplifies integration into all F&-environments and commissioning. Learning a new programming language will also become unnecessary.

Spaniard summarizes: “Epsons commitment to the further development of robotics results in this collaborative robot, which also ensures very complex tasks. This means that we meet the growing demand of the laboratory and pharmaceutical industry and other industries. This machine is significant progress on the way to improve the Epson supply in the area of industrial automation. Our robot also meet the strict requirements Life science sector and ensure security and precision with every interaction between man and machine. ”

On June 24th there will be a press conference on Epson Stand 311 in Hall B5 on June 24th

Further information on the robotic solutions from Epson:

Automatic 2025 | Epson Europe

I like it:

I like it is loaded …

Similar posts

This entry was published in Cobots, development, events, general, German, hardware, industrial robots and tagged with 2025, 6-axis robot, automatica, AX portal, AX6-A901S, Cobot, Düsseldorf, Epson, Collaborative Robot Package, RC-A101, clean room, Roboten, roboted by Sebastian Trella. Permanent link to the entry.

Source link

GIPHY App Key not set. Please check settings