Sunday Runday

(Image credit: Android Central)

In this weekly column, Android Central Wearables Editor Michael Hicks talks about the world of wearables, apps, and fitness tech related to running and health, in his quest to get faster and more fit.

This weekend, I flew to Plano, Texas, to check out Ultrahuman’s new factory. After they walked me through every official step of the process, I slipped on some gloves and started making a smart ring by hand. And it gave me a new appreciation for my own smart ring.

Smart rings aren’t designed to be taken apart and put back together like other tech. You might know what sensors are inside, but you probably don’t know what else is sitting inside all that titanium, resin, and ceramic, and what determines how thick these rings are. Ring makers don’t necessarily want you to think about what’s inside.

But with Ultrahuman’s Ring Air in the midst of a sales and patent war with the Oura Ring, the company decided to show off its new American factory. This had the nice side effect of finally sating our curiosity about how smart rings are made, something other brands have been reluctant to talk about in the past.

You may like

Plus, I get to brag that I “made” a smart ring, even if they could only let us finish certain parts of the process.

Today’s best Ultrahuman Ring Air deals

How smart rings are made

(Image credit: Ultrahuman)

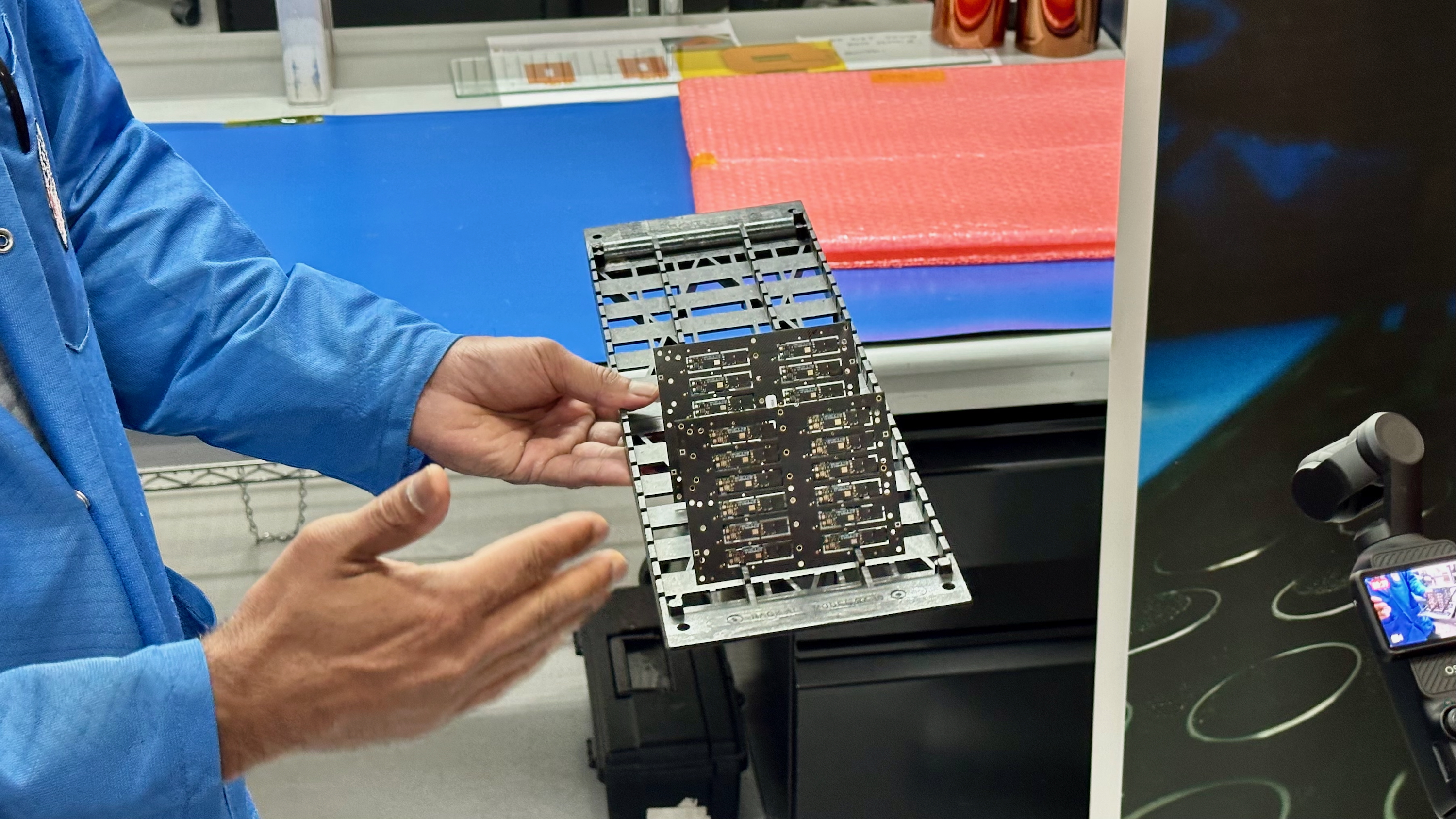

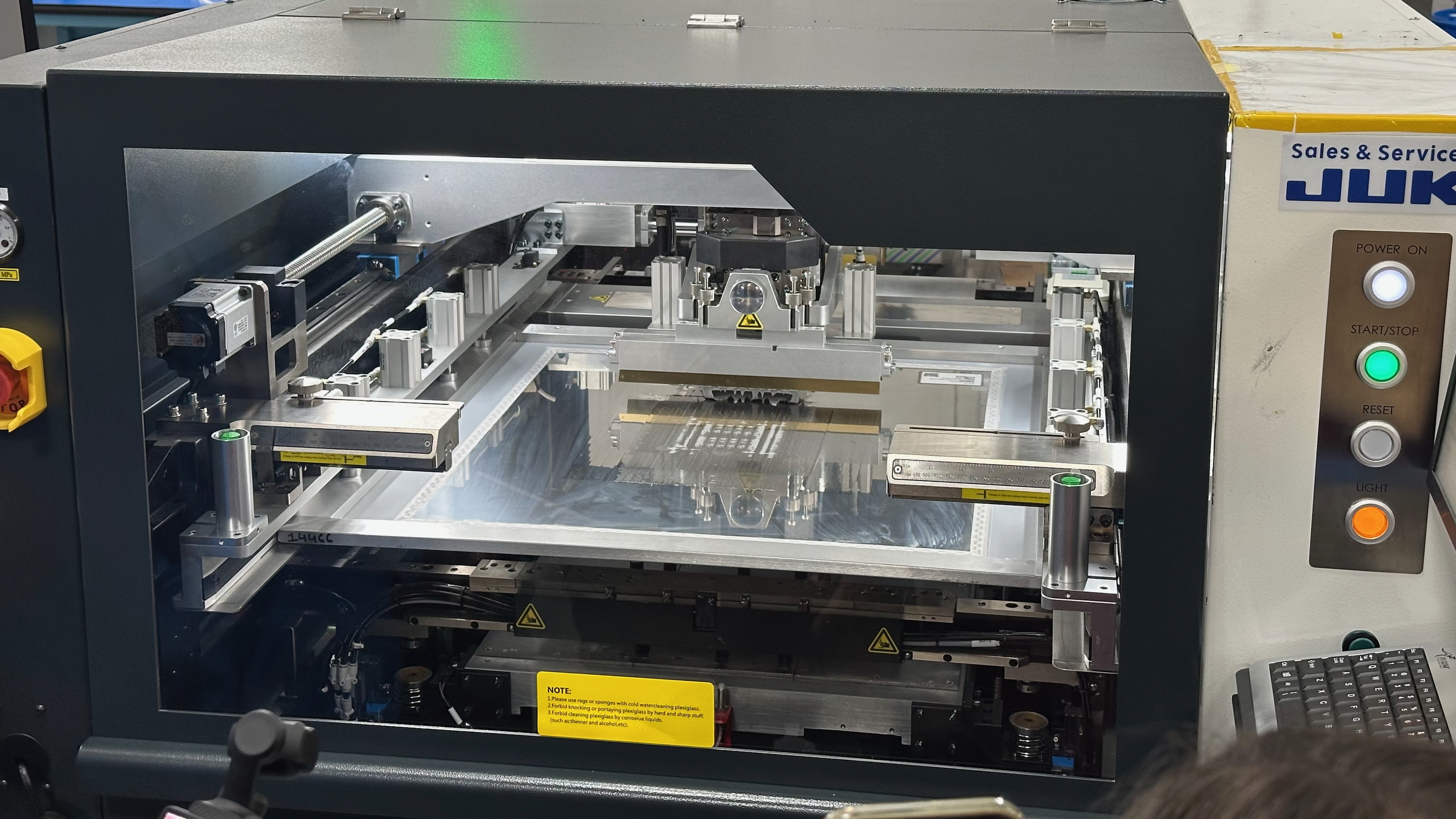

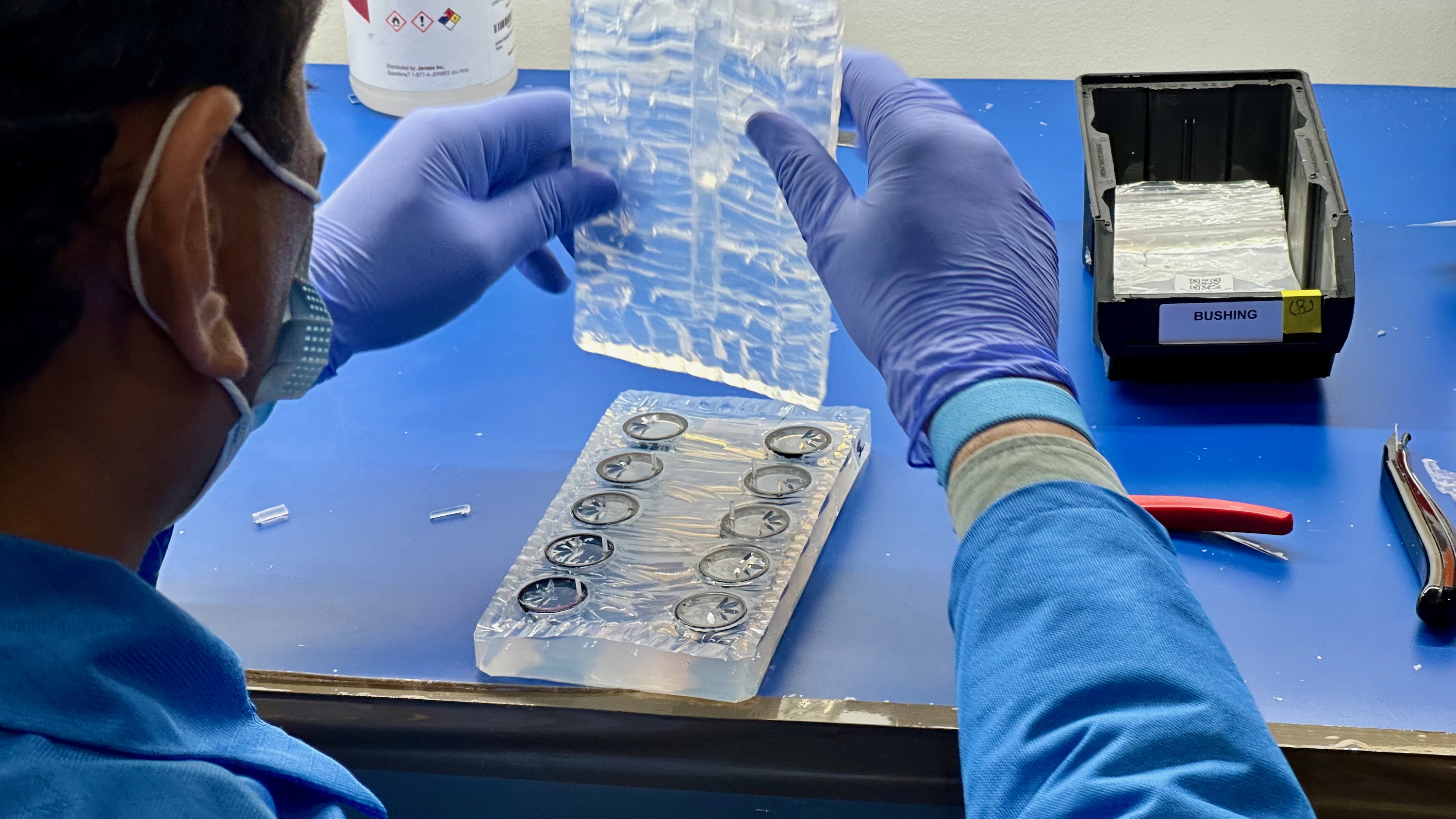

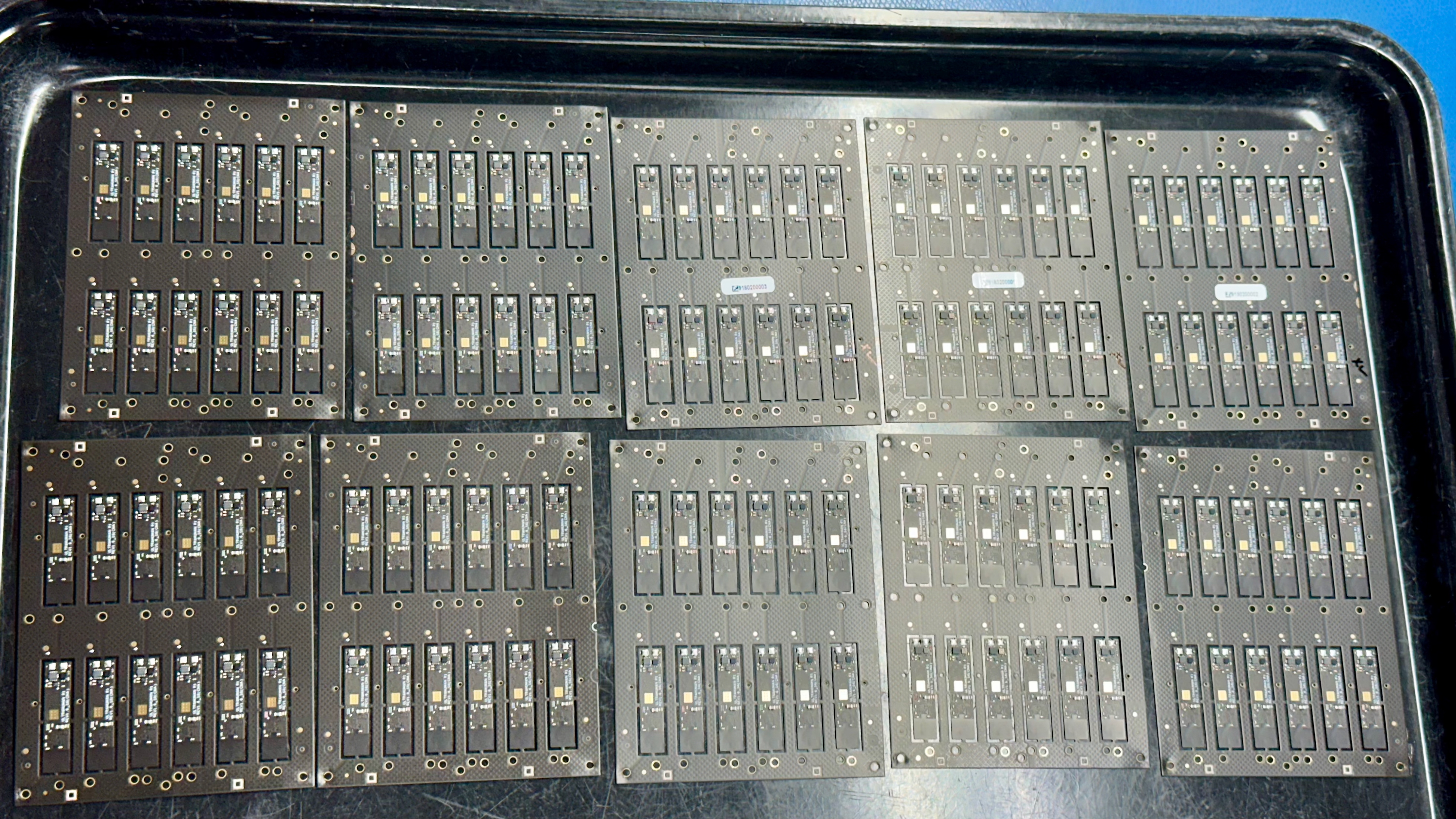

The photo galleries below show nearly every step of Ultrahuman’s smart ring-making process, starting with the creation of printed circuit boards (PCBs), which contain the SoC, PPG, IMU, temperature, and Bluetooth components.

These components are mass-producible — an engineer suggested one machine could produce 10,000 PCBs in a day — and made of fiberglass, polyamide, and ceramic materials, chosen to make them bendable enough to slide naturally into the rounded ring shape.

But the “UltraFactory” currently only makes about 400 smart rings per day, though Ultrahuman has promised to hit about 1,350 per day or 500,000 per year by the end of 2025. There are several pain points, starting with the fact that the other mass-produced components have to be soldered onto the PCB by hand.

Image 1 of 5

A standard selection of Ultrahuman Ring Air PCBs in sets of 12.(Image credit: Michael Hicks / Android Central)

A standard selection of Ultrahuman Ring Air PCBs in sets of 12.(Image credit: Michael Hicks / Android Central) The machine that mass-produces Ultrahuman Ring Air PCBs.(Image credit: Michael Hicks / Android Central)

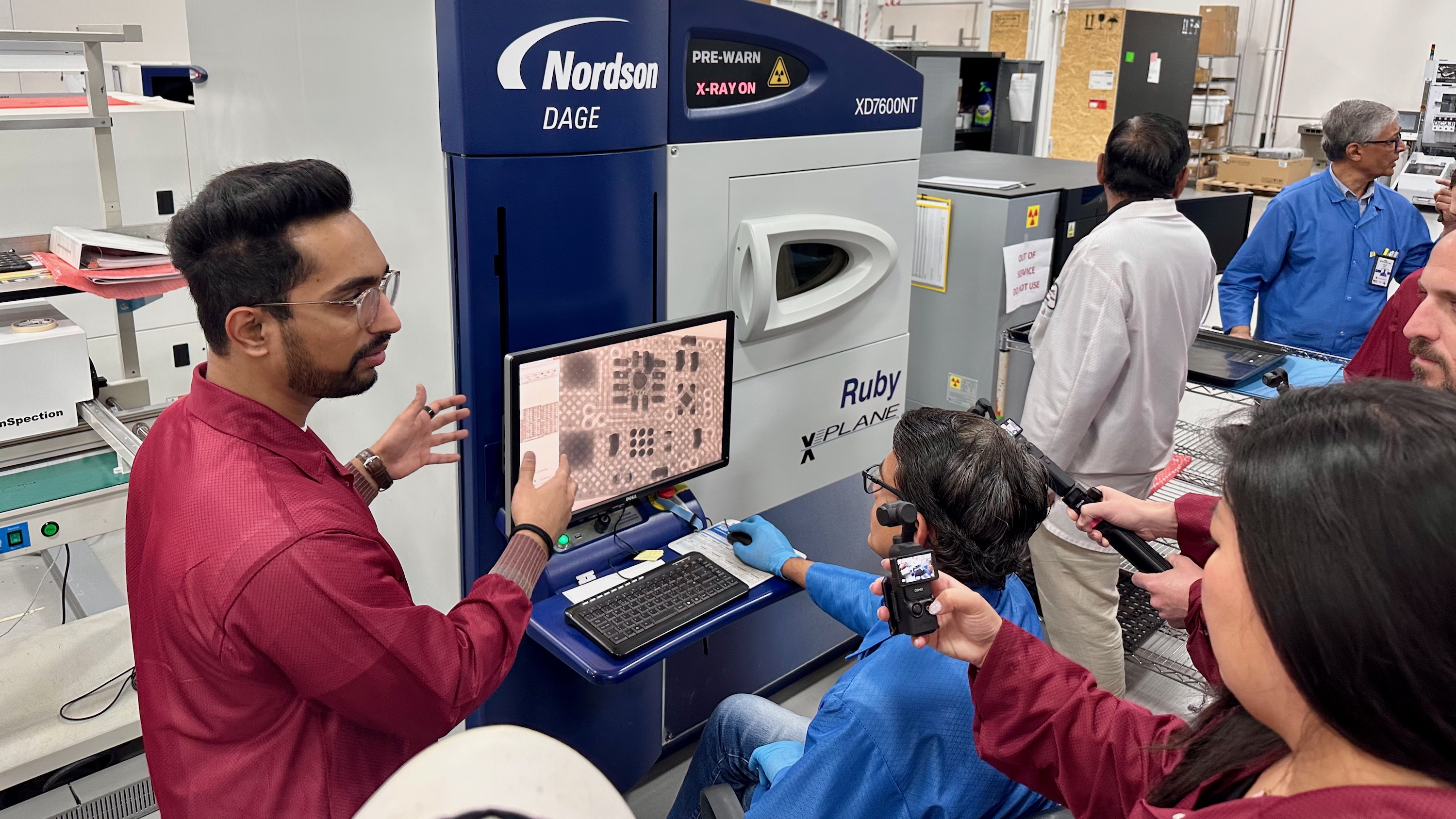

The machine that mass-produces Ultrahuman Ring Air PCBs.(Image credit: Michael Hicks / Android Central) The PCBs are placed inside an X-Ray machine to check for internal component issues.(Image credit: Michael Hicks / Android Central)

The PCBs are placed inside an X-Ray machine to check for internal component issues.(Image credit: Michael Hicks / Android Central) They then use camera close-ups to check the PCB’s external components for any major defects.(Image credit: Michael Hicks / Android Central)

They then use camera close-ups to check the PCB’s external components for any major defects.(Image credit: Michael Hicks / Android Central) Lastly, the PCBs are programmed to add the software you’re familiar with in the Ultrahuman Ring Air.(Image credit: Michael Hicks / Android Central)

Lastly, the PCBs are programmed to add the software you’re familiar with in the Ultrahuman Ring Air.(Image credit: Michael Hicks / Android Central)

After they create the PCBs, do internal and external spot checks for any flaws, and program each PCB with the requisite software, they’re ready for the next step: soldering.

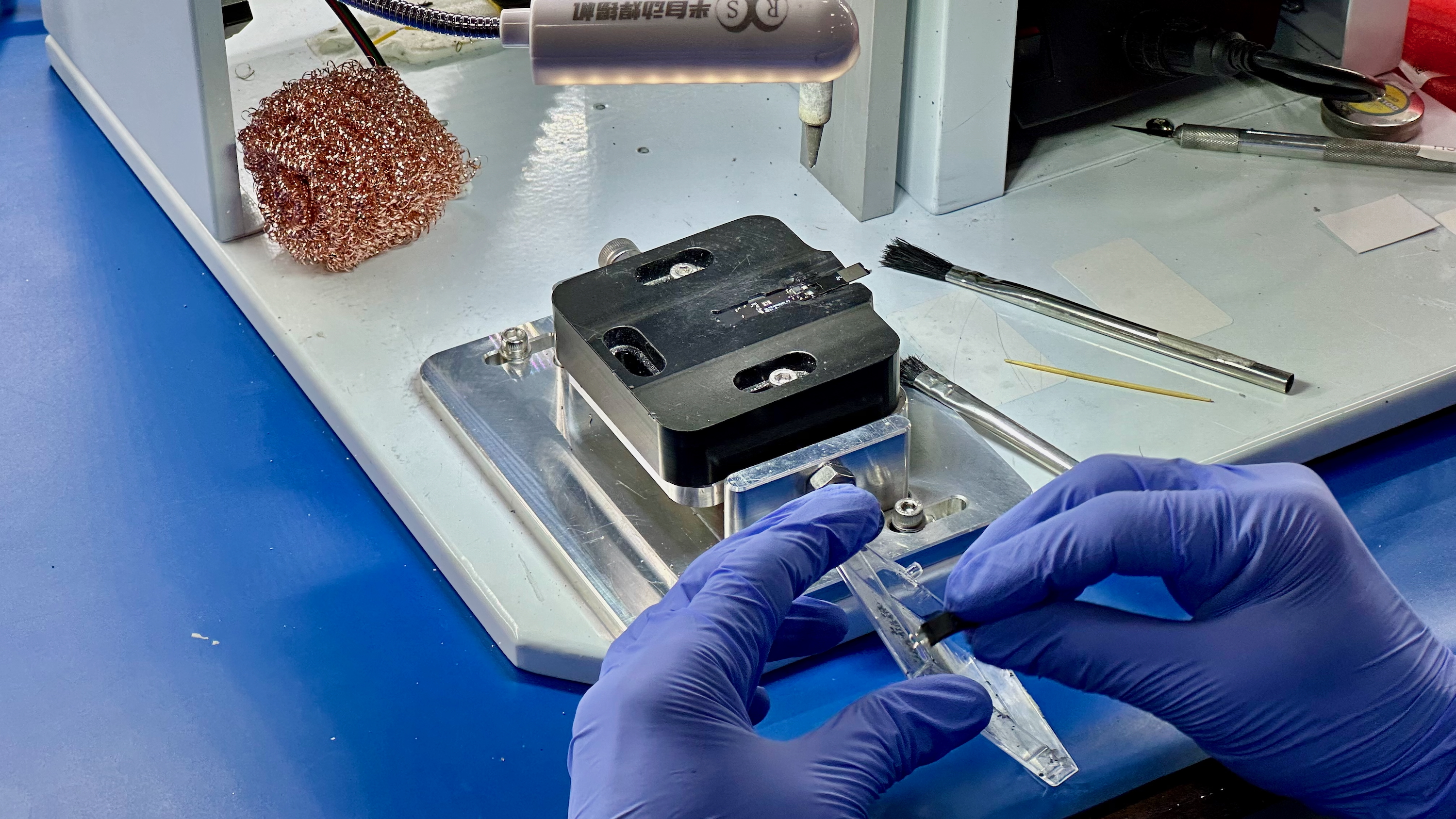

First, the Rx coil is soldered onto the PCB; then, the battery is soldered onto the coil. They brush off the excess alloy, leaving one seamless, bendable component ready to be inserted into the ring.

Image 1 of 2

Soldering the Rx coil onto the PCB.(Image credit: Michael Hicks / Android Central)

Soldering the Rx coil onto the PCB.(Image credit: Michael Hicks / Android Central) Soldering the battery onto the PCB and coil.(Image credit: Michael Hicks / Android Central)

Soldering the battery onto the PCB and coil.(Image credit: Michael Hicks / Android Central)

With a 3D-printed part, the welded-together PCB is curved into a proper J shape. The workers then apply glue to the titanium-carbon ring you’re familiar with, remove the cover for the PCB’s adhesive layer, and finally shove the component into place.

They do a software check — since technically, you could wear the ring at this point — and then place the ring inside a silicone mold. One mold with 12 rings is brought to the casting station, which is one part of the factory where they wouldn’t let us photograph or record.

There, they inject epoxy resin into the ring from the thickest portion — the PPG — inside a vacuum-sealed chamber to prevent any resin bubbles. The process takes 24 hours, because heating the resin to harden it faster would damage the components. Ultrahuman said this casting process is one of the big pain points that slows down the ring process.

Image 1 of 6

The worker places glue on the smart ring to attach the PCB.(Image credit: Michael Hicks / Android Central)

The worker places glue on the smart ring to attach the PCB.(Image credit: Michael Hicks / Android Central) They test the PCB’s software and functionality before sealing the components in resin, so they can fix things first.(Image credit: Michael Hicks / Android Central)

They test the PCB’s software and functionality before sealing the components in resin, so they can fix things first.(Image credit: Michael Hicks / Android Central) The rings are placed inside a silicone mold.(Image credit: Michael Hicks / Android Central)

The rings are placed inside a silicone mold.(Image credit: Michael Hicks / Android Central) Removing the silicone layer after injecting epoxy resin inside of the smart rings.(Image credit: Michael Hicks / Android Central)

Removing the silicone layer after injecting epoxy resin inside of the smart rings.(Image credit: Michael Hicks / Android Central) How a smart ring looks after injected with epoxy resin(Image credit: Michael Hicks / Android Central)

How a smart ring looks after injected with epoxy resin(Image credit: Michael Hicks / Android Central) Buffing the smart rings to remove the hard-edged pieces of resin remaining.(Image credit: Michael Hicks / Android Central)

Buffing the smart rings to remove the hard-edged pieces of resin remaining.(Image credit: Michael Hicks / Android Central)

At this point, the smart ring is almost ready to be worn, but the resin will look rough and have hard edges that’ll hurt your finger. They spend about 30 minutes cleaning and polishing it into consumer-ready form.

Once that’s done, they do one more software check to ensure everything is up to code. Then, they place the ring on a 3D-printed part to check its size; if it won’t fit or slides all the way down the cylinder, they know it’s not to code. Otherwise, the Ultrahuman Ring Air is ready to be sold!

How I made a smart ring

(Image credit: Michael Hicks / Android Central)

If you’ve been paying attention, you’ll note that I couldn’t make a smart ring from start to finish during this tour. The 24-hour resin process made that impossible. So it’s more accurate to say that I got halfway through making a smart ring and then returned a different smart ring for the final part of the process. Nor did I get to handle any software or hardware QC.

I’m still going to say I made a smart ring, though. They told me my halfway-done smart ring would eventually be sold to someone, and that’s pretty neat.

Image 1 of 3

I soldered both the receiver coil and battery onto the PCB.(Image credit: Michael Hicks / Android Central)

I soldered both the receiver coil and battery onto the PCB.(Image credit: Michael Hicks / Android Central) Then I removed the adhesive material and inserted the components into a smart ring.(Image credit: Michael Hicks / Android Central)

Then I removed the adhesive material and inserted the components into a smart ring.(Image credit: Michael Hicks / Android Central) With that done, I inserted my ring into a mold to be sent to the casting machine.(Image credit: Michael Hicks / Android Central)

With that done, I inserted my ring into a mold to be sent to the casting machine.(Image credit: Michael Hicks / Android Central)

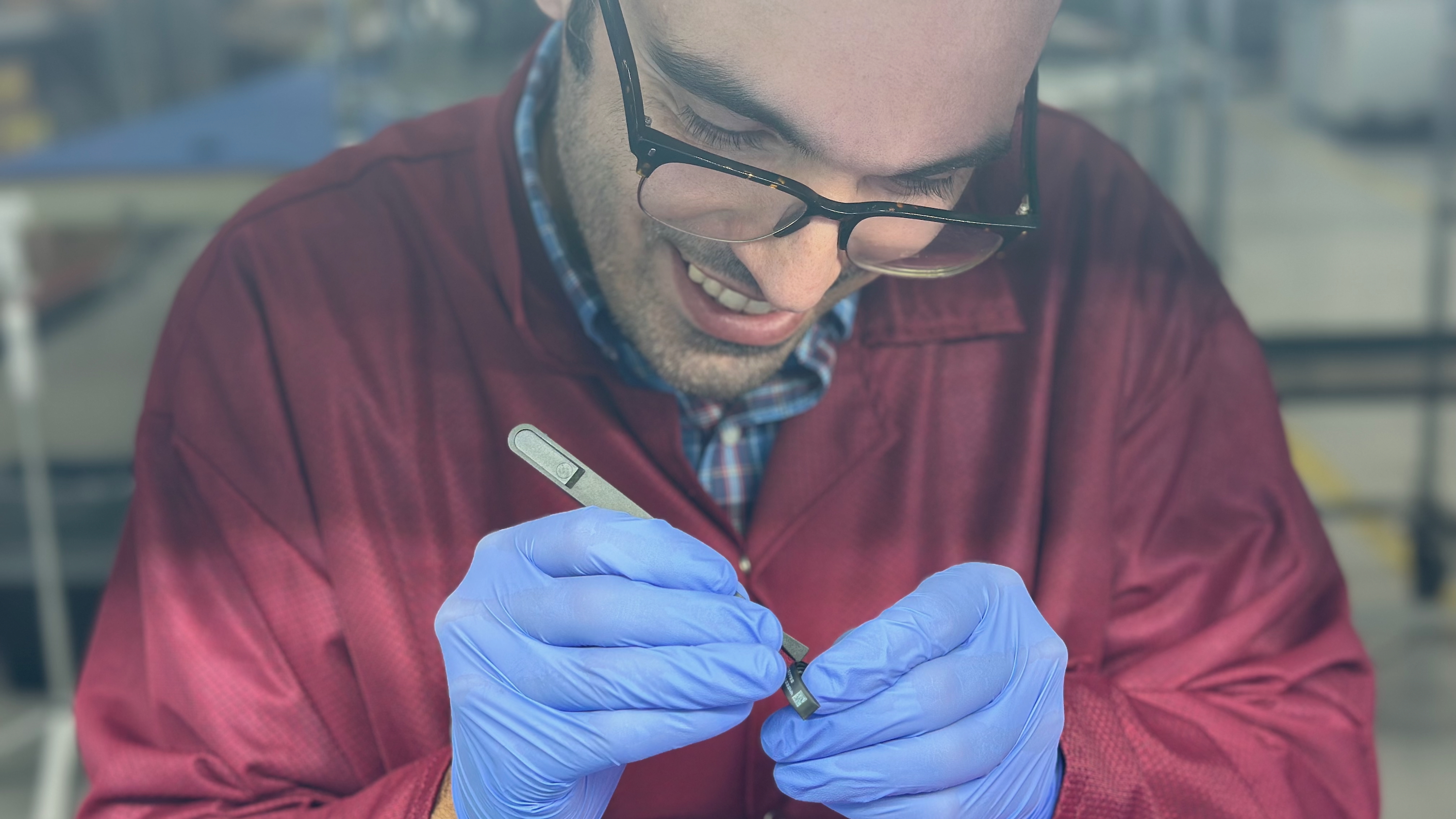

Following the steps above, I soldered the receiver coil onto the PCB by scraping some adhesive onto the coil and then stepping on a switch to trigger the machine (without burning off my thumbnail, thankfully). I then had to solder two separate points to attach the battery before brushing away the excess adhesive.

I curved the Ring Air components so they would fit inside, ripped off the adhesive with tweezers, shoved them inside the ring, and then pressed hard on the sensors to make them stick.

I was sure my clumsy, shaking fingers would break something, but it turned out my only issue was being too gentle. One portion came loose as I started to shove my smart ring into the casting mold, but I got it reattached and waved farewell to my ring.

Then they gave me another ring further along in the process and had me clean off the resin, using an electric spinning brush, sandpaper, and some 3M buffing fluid. I didn’t get to finish the full 15+ minutes before Ultrahuman staff hustled me along to my interview, but I can honestly say I got that Ring Air into good enough shape that the resin wouldn’t cut any fingers or look unsightly.

How smart ring manufacturing might change

(Image credit: Michael Hicks / Android Central)

I asked Ultrahuman’s CEO, Mohit Kumar, and chief business officer, Bhuvan Srinivasan, about smart ring repairability, a major issue with all smart rings. The resin that keeps components in place and protected also makes it all but impossible to take rings apart for repair, and there are no visible buttons for resetting a malfunctioning ring.

They explained that they hope to add a tiny, hidden button to their smart rings. If a Ring Air is sent in for repair, they’ll be able to remove a tiny bit of resin to hold down that button and reboot the ring into a mode where it can receive firmware updates.

I asked if they had any hopes for a more modular design that would let them remove and replace a battery, since smart ring batteries are so small and susceptible to losing capacity after a couple of years. Kumar replied that they’re interested in it, but I got the sense that it’s more of a pie-in-the-sky goal than something they’re actively pursuing at the moment.

(Image credit: Michael Hicks / Android Central)

For now, they’re more focused on optimization. Because American labor costs are higher than in their Indian facility, they’re looking to make the process more efficient; for example, they found a new casting machine that would inject resin into four times as many rings at once, breaking open that bottleneck in the factory line.

As for me, I’m curious how the manufacturing processes of other smart rings differ from those of Ultrahuman and how they are evolving as the tech improves. But proprietary differences aside, the UltraFactory experience gave me respect for the amount of quality control that goes into making a smart ring — while also surprising me that someone like me with no industrial experience can go through the steps with enough hand-holding and patience.

GIPHY App Key not set. Please check settings